17 Jun, 2014

After much worry and swapping a half inch coil that I thought would be too tall for a 3/8th inch one, the actual fitting went very smoothly. I can now control the temperature of the mash, putting me a lot closer to doing a brew :)

The pressure sensor dip tube for volume measurement also proved painless to fit and can be seen to the right of the coil.

10 Jun, 2014

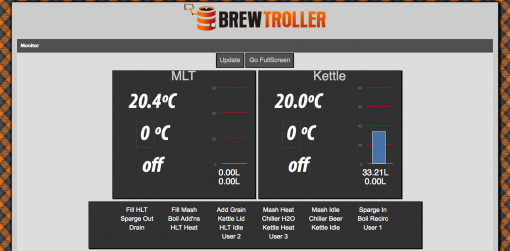

Network up and linked via custom PHP script and serial <-> ethernet bifferboard bridge

10 Jun, 2014

Temperature sensors installed in the plate chiller – measuring H2O in, H2O out, Beer in (measured at kettle exit) and Beer out

09 Jun, 2014

Using a Bus Pirate to update the firmware on the Brewtroller – the Bus Pirate was set to communicate at 57600bps both PC side and client side, and then put into Transparent Bridge mode to allow the Arduino software (and in turn avrdude) to reprogramme the Sanguino microcontroller.

07 Apr, 2014

After an initial explosion where the hose came off the tap and covered the floor, walls and ceiling in cold water, the test didn’t go too badly. The main problems were:

- Leaking around the kettle elements due to the nuts only being hand tightened. Apparently I need a c-spanner to tighten them.

- A valve got stuck open and wouldn’t respond to commands, but started working again after being off for a few minutes. This needs investigating as a faulty valve during a brew could quite easily ruin the brew and cause a lot of problems.

- Pump being switched on at the same time as the valves opening caused air to get trapped in the lines. Turning the pump off for a few seconds purged the lines of air and make transfers of liquid much quicker – a delay before switching the pump on after opening valves would solve this problem.